The Invisible Profit Engine of E-Commerce: A Guide to Protecting Brand Integrity with Advanced Inventory Management

Inventory Management – The Unseen Source of Profitability

E-commerce success is often simplified down to core elements like a great product and effective marketing. Yet, the critical area that the most successful brands quietly master—and that sets them apart from the competition—is Inventory Management.

Traditionally, inventory management was seen as simply counting boxes in a warehouse. Today, this function is strategic: it directly controls cash flow, ties up or frees capital, and most importantly, protects your brand's reputation.

In this guide, we will prove that inventory management is a profit engine, not just a cost center. We will expose the financial costs of operational inefficiencies and analyze how a technology-focused Warehouse Management System (WMS) solution (like Ship.house) provides an indispensable competitive advantage.

E-Commerce's Biggest Hidden Costs: Overstocking vs. Stockouts

The greatest inventory challenge is balancing two opposing risks:

- Stockout: When a high-demand product is unavailable, it results in direct lost sales revenue and permanent damage to customer loyalty.

- Overstocking: Holding excessive inventory leads to extra storage fees and, most critically, blocked cash capital. This capital could be fueling growth but is instead sitting idle on your shelves.

Key Takeaway: Poor inventory decisions are insidious costs that devour your profitability.

The Critical Link Between Logistics and Customer Trust

Modern e-commerce customers demand fast delivery, 100% accuracy, and transparency. A single error in the fulfillment process can quickly undermine all your branding efforts.

McKinsey data indicates that 85% of customers who experience a poor delivery (wrong item, delay) will not shop with that retailer again. Fulfillment has become a crucial brand risk management tool.

The Inventory Accuracy Paradox: Visibility is Everything

Even a 1% error margin in your inventory data can trigger a massive domino effect in your supply chain, breaking the crucial link between operational efficiency and financial profitability.

The Chain Financial Effects of Inaccurate Inventory

Inaccurate inventory inflates costs on multiple fronts:

- Wrong Purchasing Decisions: Ordering stock mistakenly thought to be out of stock leads to overstocking and inflated procurement costs.

- High Labor Costs: Warehouse staff wastes time searching for "ghost stock"—items that appear in the system but aren't physically present.

- Incorrect Packaging and Returns: Errors increase the probability of sending the wrong product, initiating costly reverse logistics, shipping fees, and processing costs.

The Direct Impact of Inventory on Cash Flow

Inventory is often the largest illiquid asset for an e-commerce business. Smart inventory management quickly identifies slow-moving stock, converts it into cash through liquidation, and allows you to channel that freed capital toward high-growth areas (marketing, R&D).

Simply put: The better you manage your inventory, the healthier your cash flow and the faster you can scale your business.

The Modern Logistics Solution: WMS and the Automation Revolution

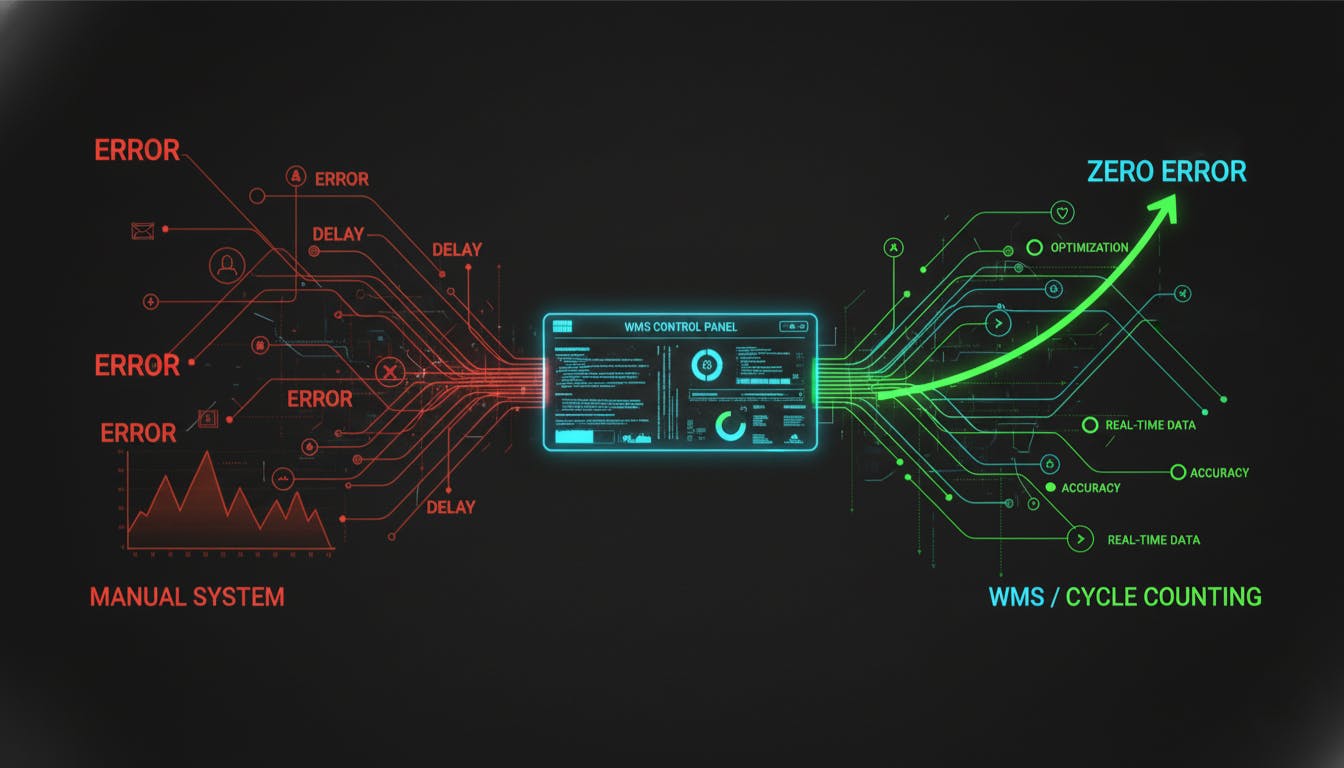

The sheer volume and velocity of e-commerce today have rendered manual systems (Excel spreadsheets) obsolete. Modern inventory necessitates an upgrade to advanced technology.

Continuous Accuracy Through Cycle Counting

The traditional annual physical count is disruptive and error-prone. Cycle Counting (supported by a WMS) offers clear advantages:

- Uninterrupted Operation: The warehouse continues working while small sections are verified periodically.

- Error Reduction: The WMS automatically flags high-value or high-risk items for counting, which can increase operational efficiency by up to 20% and reduce reliance on costly manual checks.

How WMS Approaches a Zero Error Rate

Advanced Warehouse Management Systems are designed to minimize operational mistakes:

- Barcode/RFID Enforcement: The WMS prevents acceptance or picking without scanning, virtually eliminating the possibility of the wrong product going to the wrong location.

- Smart Pick-Path Optimization: The WMS guides personnel along the most efficient routes, increasing speed and preventing staff from wasting time or making errors.

- Automation and AI: Case studies show robotics dramatically reduce human error, shortening picking time and lowering labor costs. A tech-focused 3PL can offer these automation benefits to smaller brands cost-effectively.

Measuring Performance: The Most Critical Inventory KPIs

Effective inventory management requires continuous tracking of the right metrics. These KPIs are strategic command tables that drive purchasing, pricing, and marketing decisions.

Analyzing Efficiency: Inventory Turnover and Days Sales of Inventory (DSI)

Two fundamental metrics that show how efficiently your inventory is being utilized and how quickly your capital is cycling are Inventory Turnover and Days Sales of Inventory (DSI). Inventory Turnover measures the frequency with which stock is sold and replenished. You calculate it by dividing the Cost of Goods Sold (COGS) by the Average Inventory. Strategically, aiming for a high turnover rate is crucial, as this indicates lower holding costs and more efficient use of your stock. Days Sales of Inventory (DSI), conversely, shows the number of days required to sell all the inventory you have. It is calculated by multiplying 365 days by the ratio of Average Inventory to COGS. While the ideal figure varies by industry, aiming for a low DSI is always desirable, as it means capital is blocked less in inventory and cash flow is being freed up faster. Both of these metrics are vital indicators that guide your purchasing, pricing, and marketing decisions.

Fill Rate: The Guarantee of Customer Satisfaction

The Fill Rate measures the percentage of orders completely fulfilled in the first shipment.

- Formula: (Completely Fulfilled Orders / Total Orders) $\times$ 100

- Importance: This directly reflects the level of customer service and operational reliability. A Fill Rate below 99% means constantly failing to meet customer expectations and carrying the 85% customer loss risk mentioned above. A high Fill Rate is proof of how flawlessly your WMS and processes are operating.

Safety Stock Management and Reorder Point Determination

Smart WMS solutions use these KPIs to automatically determine Reorder Points and calculate the necessary Safety Stock level.

- JIT (Just-in-Time) Strategies: The goal is to receive stock exactly when needed. The WMS analyzes past sales data, lead time, and reliability (Supplier performance) to suggest the minimum safety stock level that will not lead to a stockout.

- Data-Driven Purchasing: This ensures brands make purchasing decisions based on proven usage data (Stock Usage by Day), not risky guesses, thereby eliminating unnecessary expenditures and overstocking costs.

Competitive Edge: Lessons from the US Market

The fulfillment competition in the US market, Ship.house’s primary focus, is increasingly driven by technological transparency and flexibility, not just pricing.

The Trap of Hidden Costs in 3PL Pricing Models

Typical 3PL cost structures are complex and fragmented (storage, receiving, picking, returns, account management). Operational fees like Receiving ($750) can often be perceived as hidden costs due to this complexity.

Strategic Insight: A tech-focused WMS solution like Ship.house can automate receiving processes, significantly reducing these hidden operational costs. This approach offers a transparent and predictable cost structure that acts as a serious competitive advantage against complex rival pricing.

Flexibility for Niche Brands: Kitting and Customization

Many large, rigid fulfillment providers (like some in the US market) do not offer complex or customized product assembly (kitting) services required by subscription box or personalized gift brands.

The ShipHouse Advantage: This market gap means that platforms like ShipHouse can attract niche brands that require customized operations.

Conclusion: Why Inventory Management is a Strategic Investment

Inventory management has transformed from a cost center into a strategic investment and a source of growth capital for e-commerce brands. Success now depends on translating operational data into profitable financial decisions.

The Vision Technology Provides:

- Financial Health: WMS protects your cash flow by mitigating the risks of stockouts and overstocking, channeling freed capital into high-growth areas.

- Operational Excellence: WMS-based processes like cycle counting reduce labor costs and drive the error rate close to zero.

- Delivery Reliability: A high Fill Rate guarantees operational reliability and eliminates the high risk of customer churn, ensuring consistent service quality.

The future belongs to data-driven, integrated WMS solutions. To unlock your brand's full growth potential and avoid common cost traps, prioritizing a partner with technological flexibility and data accuracy is your most important strategic decision in today's competitive market.

ShipHouse: Simple, Reliable, and Cost-Effective Inventory Management

ShipHouse is designed to remove the complexity from inventory management and order fulfillment. Without requiring high integration costs or massive volume commitments, it simplifies stock tracking, ensures accurate and timely preparation, and significantly reduces the daily operational burden. With transparent pricing, it eliminates surprise costs while strengthening both your cash flow and customer satisfaction through regular checks, rapid receiving, and meticulous packaging.

ShipHouse makes operational processes easy, so you can focus your energy on growing your business.